Alongside its range of diesel engines, Liebherr is shining the spotlight at Bauma 2025 on alternative fuels by showcasing a working hydrogen unit and a modular injection system capable of accommodating a wide range of alternative fuels

In the context of the energy transition applied to propulsion systems for industrial machinery, Liebherr is presenting two solutions at Bauma 2025 that, though different in nature, converge towards a common goal: drastically reducing environmental impact without compromising the reliability, durability, and performance required for off-highway applications. On one hand, the new “H9X6” engine; on the other, the innovative “LiGo” injection platform.

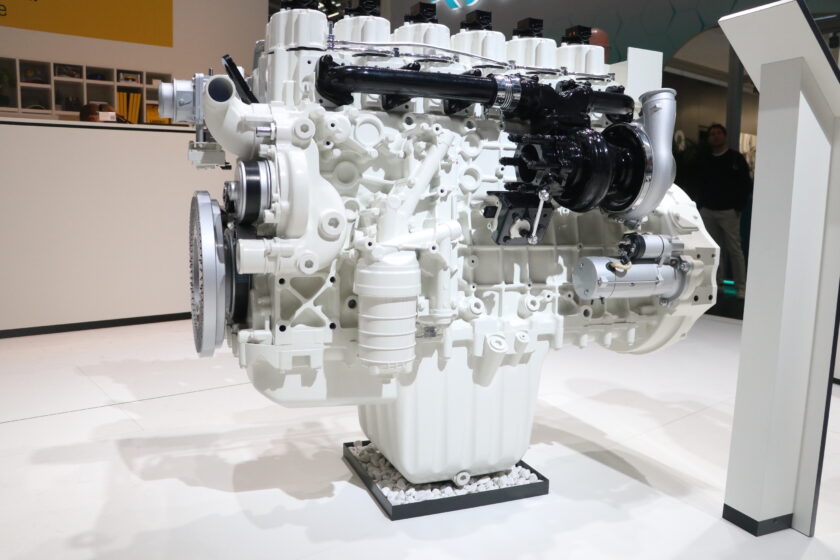

The “H9X6” is a 13-liter inline six-cylinder engine developed specifically to run on hydrogen, utilizing an indirect “Port Fuel Injection” system that operates at pressures below 20 bar. This precise design choice enables clean and efficient combustion, with carbon dioxide and nitrogen oxide emissions close to zero. Unlike many alternative solutions still in the experimental phase, the “H9X6” is designed to provide a concrete response that can be easily integrated into existing machinery. Its compact and robust structure, thermal and mechanical interfaces similar to those of diesel engines, and dynamic operation make this unit perfectly adaptable to multiple operational scenarios—particularly in the construction and agricultural sectors, where resistance to external elements, service continuity, and ease of maintenance remain essential requirements.

Towards sustainability

However, Liebherr’s approach is not limited to engine development; it also encompasses the entire fuel management chain. This is where the “LiGo” system comes into play—a modular injection platform developed to support the use of alternative fuels such as hydrogen, methanol, ethanol, and ammonia. “LiGo” can be configured for both indirect and direct injection, offering manufacturers unprecedented flexibility in designing alternative propulsion systems. The core of the system consists of a series of integrable components, including the “Lpi” and “Ldi” injectors, the pressure and fuel quantity control module, and the distribution rail. All elements are designed to work synergistically and adapt to multiple engine layouts, with the goal of reducing development time and costs while ensuring high dosing precision and repeatability in fuel management.

This solution represents not only a technical option but also a genuine industrial strategy aimed at accelerating the adoption of low-impact powertrains. Liebherr’s approach stands out for its concreteness and scalability in a market where environmental regulations are becoming increasingly stringent, and the pressure to reduce the carbon footprint is growing at every level of the production chain.

Titolo: Engines Liebherr: hydrogen and modularity

Translation with ChatGPT